Call us Now!

(888) 367-3011(888) 367-3011

English Spanish

Crankshaft Rebuilding & Balancing

Crankshaft Rebuilding

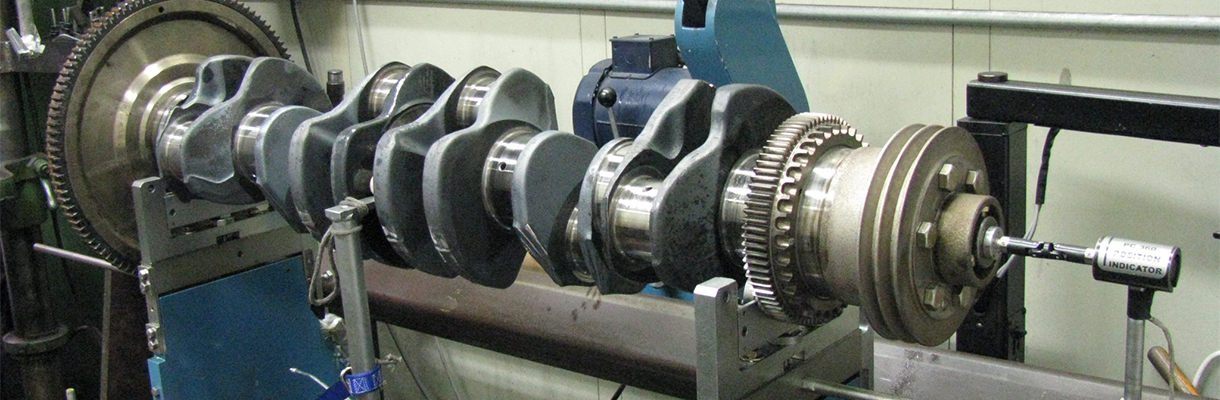

All crankshafts are first cleaned and wet magnafluxed for cracks. All oil gallery plugs are removed. After than procedure, all cranks are inspected for straightness, journal sizes, thrust end play, and hardness. Crankshafts are then straightened if they are bent. Crankshafts are then polished or reground to factory OEM fillet radius specifications. After a crank is reground it is then final cleaned and oil plugs installed (when necessary) and bagged.Crankshaft Balancing

At the customers request, crankshafts are checked for vibration by checking balance. Vibration dampeners, flywheels, flex plates are added to check the balance of them as well. By balancing an engine, the engine will run at optimum performance, less vibration and more longevity. We also balance any rotating shaft as well.

Email us at [email protected]