Call us Now!

(888) 367-3011(888) 367-3011

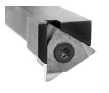

O-Ring Groove Cutter

Click here for engine information.

BHJ's O-Ring Groove Cutter is the solution for eliminating misalignment when cutting O-ring and receiver grooves. By using this specially designed cutter in conjunction with application-specific Register Plates (sold separately), absolute concentricity of the top and bottom grooves is insured.

Use of the Cutter and O-Ring Register Plate gives excellent results when cutting grooves in the block and/or heads. This operation is typically necessary when using copper head gaskets with stainless steel wire, copper wire with an MLS gasket, diesel or Top Fuel "fire rings" and the Fel-Pro Loc-Wire™ head gasket.

Cutting Inserts are available in a variety of sizes to accommodate current, popular groove widths for gas and diesel applications. Inserts are custom-ground on centerline, which eliminates the need to reset groove diameter when grooves of different widths are required between the block and head.

Applications range from small-bore import engines to diesels, by installing or removing the large-bore Register Ring for most V6 and larger engines, or removing it to accommodate the close bore-centers found in many import motors. This new feature is available standard with all new O-Ring Groove Cutters. Conversion of older model O-Ring Groove Cutters to work with small-bore Register Plates is also available.

Groove diameter is precisely set using a special Dial Indicator, which is included with the Cutter. Accuracy of the groove diameter is within .002" and groove depth is easily adjusted with the built-in micro stops, with accuracy within .001". Diameters range from 2.400" to over 5.125", based on application.

Groove diameter is precisely set using a special Dial Indicator, which is included with the Cutter. Accuracy of the groove diameter is within .002" and groove depth is easily adjusted with the built-in micro stops, with accuracy within .001". Diameters range from 2.400" to over 5.125", based on application.

Using the O-Ring Groove Cutter with the appropriate Register Plate, an automotive machinist can accurately groove a pair of V-8 heads in just over one-hour, or a block and heads in approximately two and a half hours. Cylinder heads may be cut without first being stripped, as the chips are fully contained in the register plate bores during cutting. Each Kit includes one Cutter Unit, four Hold Down Knobs, a 1"-travel Dial Indicator with Tip, one Carbide Insert (choose size when ordering), a Torx Wrench, two Hex Key Wrenches and a Zeroing Pin.

BHJ's O-Ring Groove Depth Gauge is available separately and is used to verify groove depths during the cutting process. After cutting the groove and removing the Cutter Head, the Gauge rests on the Register Plate surface and zero is set on the deck surface. The tip is then set into the groove in any of four locations around each bore and the groove depth is easily verified.

BHJ's O-Ring Groove Depth Gauge is available separately and is used to verify groove depths during the cutting process. After cutting the groove and removing the Cutter Head, the Gauge rests on the Register Plate surface and zero is set on the deck surface. The tip is then set into the groove in any of four locations around each bore and the groove depth is easily verified.

A 4" Short Handle option is available for engine builders wising to groove inline-6 cylinder engines while still in the vehicle. The Short Handle provides clearance from the firewall when cutting the rear cylinder in the block and is commonly used for Cummins diesel applications.

A 4" Short Handle option is available for engine builders wising to groove inline-6 cylinder engines while still in the vehicle. The Short Handle provides clearance from the firewall when cutting the rear cylinder in the block and is commonly used for Cummins diesel applications.

Replacement cutting Inserts are available in standard widths of .039", .048", .050", .060", .085", .120" and .125" and are also available in custom widths on a special-order basis. One-pound rolls of Stainless Steel or Copper Wire are also available in .041" and .051" diameters.

O-Ring Register Plates are designed to work specifically with BHJ's O-Ring Groove Cutter. Each Plate is engine-specific and locates on the dowel holes in both the block and heads, thus ensuring precise alignment of the grooves when assembled. Through-holes and threaded holes are machined into each Plate for fastening to both the block and head. Plates are available for virtually any currently available block and/or head. Each O-Ring Register Plate is supplied with the appropriate dowel pins for mounting to the block and head.

O-Ring Register Plates are designed to work specifically with BHJ's O-Ring Groove Cutter. Each Plate is engine-specific and locates on the dowel holes in both the block and heads, thus ensuring precise alignment of the grooves when assembled. Through-holes and threaded holes are machined into each Plate for fastening to both the block and head. Plates are available for virtually any currently available block and/or head. Each O-Ring Register Plate is supplied with the appropriate dowel pins for mounting to the block and head.