Call us Now!

(888) 367-3011(888) 367-3011

Shims by Rutt's Machine

CUSTOM SIZE LINER SHIMS

HIGH QUALITY STAINLESS STEEL SHIMS

Cummins/Caterpillar/Detroit/Paccar – 125 Different Stocking Sizes

Precision Liner Height Adjustment for Optimal Performance

What Are Shims?

Liner shims are thin, precisely-crafted pieces of material used to adjust the alignment of engine components. Whether you’re dealing with misaligned motors or other engine parts, our shims offer an easy and effective way to achieve optimal alignment, reducing vibration, wear, and tear while improving the overall performance and lifespan of your equipment.

Why Choose Rutt's Machine Liner Shims?

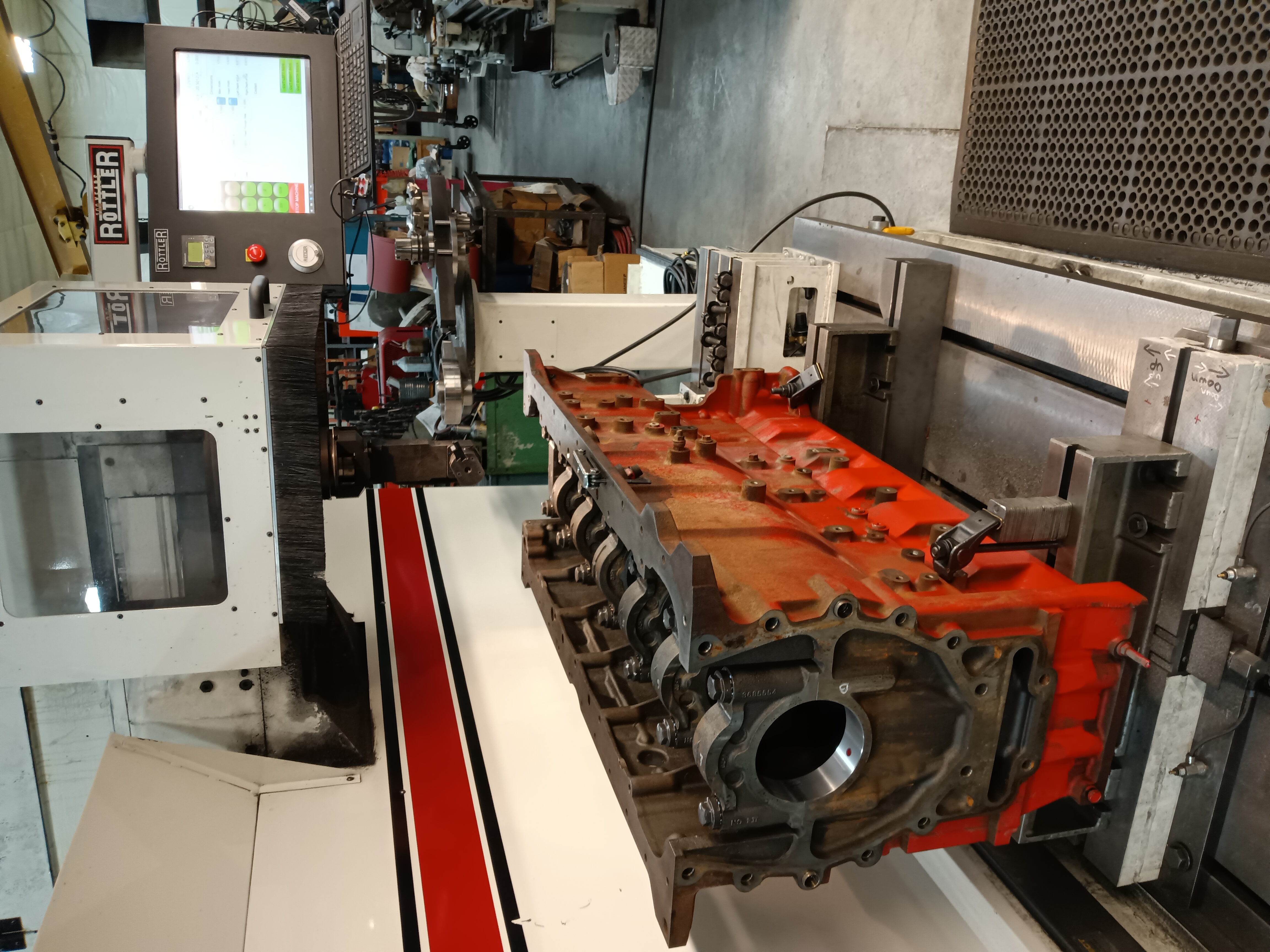

On-Site Service

Rutts Machine has two dedicated employees who perform on-site counterbore machining, to set the liner height, to spec.

Unmatched Quality

Our custom-made shims are machined from pipe stock, with a CNC lathe. The material used is a special high-durability formula of industrial-grade stainless steel, forged with additives to increase durability and reliability. Each shim is designed to withstand the demands of the most grueling conditions, guaranteeing long-lasting performance.

Precision Engineering

At Rutt's Machine, we pride ourselves on precision. Our liner shims are engineered to exact specifications, ensuring perfectly accurate alignment adjustments with minimal effort. This precision helps maintain the integrity of your machinery, preventing operational issues and costly downtime.

Versatility

We make use of dedicated high-precision computer-controlled equipment to machine our stock for shims perfectly to your required height.

We can also produce completely custom-made shims with all dimensions machined according to your precise specifications.

Easy to Use

With Rutt’s Machine Liner Shims, achieving your desired height is a breeze. Our shims are designed for quick and hassle-free installation, ensuring you can maintain the proper liner height on your engine quickly and reliably.

Benefits of Using Shims

- Improved Equipment Efficiency: Proper alignment reduces friction and wear, leading to more efficient machinery operation.

- Extended Lifespan: By preventing misadjusted liner height, our shims help extend the life of your equipment, saving you money in the long run.

- Reduced Maintenance Costs: Correct liner height minimizes the need for frequent repairs and maintenance, reducing overall operating costs.

Our Product Range

Rutt’s Machine offers a wide selection of custom-made, stainless-steel shims, specifically designed to adjust liner heights on many different engine types and models.

“No Machining Shims” (for Cummins ISX)

One common cause for head gasket failure on a Cummins ISX is the failure of the original brass shims, which have been smashed or broken into pieces. In many such cases (with brass shims) the engine counterbores are not damaged at all. We can save you from having to machine new counterbores by providing stainless steel replacement shims that restore the liner back to the high side spec, without having to machine the counterbores.

Why Rutt’s Machine?

Choosing Rutt’s Machine means investing in a brand that stands for quality, precision, and reliability. Our commitment to excellence ensures that you receive the best products and services available. With decades of experience in the industry, we understand the importance of accurate alignment and are dedicated to providing solutions that meet and exceed your expectations.

Quality control is vital in our company. Our goal is to ship orders with a 100% satisfaction rate.

Get Started Today!

Don’t compromise on the tolerance of your engines! Trust Rutt’s Machine for all your line height shim needs. Your machinery deserves the best, and so do you.

For custom orders or more information, contact our expert team. We're here to help you achieve perfect alignment every time.

GET THE SHIMS YOU NEED NOW

Call us at 717-367-3011 for a complete list of our stock shims, which we can e-mail to you. Also, contact Donald, to order custom-made shims 717-368-8532. All we need is ID and OD, and the preferred thickness required. (.020” min thickness)